bull nose end mill vs flat end mill

Ball Nose Milling Without a Tilt Angle. 3 Flute End Mills.

End Mill Itu Apa Sih Fungsi Dan Kegunaannya Pt Indonesia Surya Sejahtera

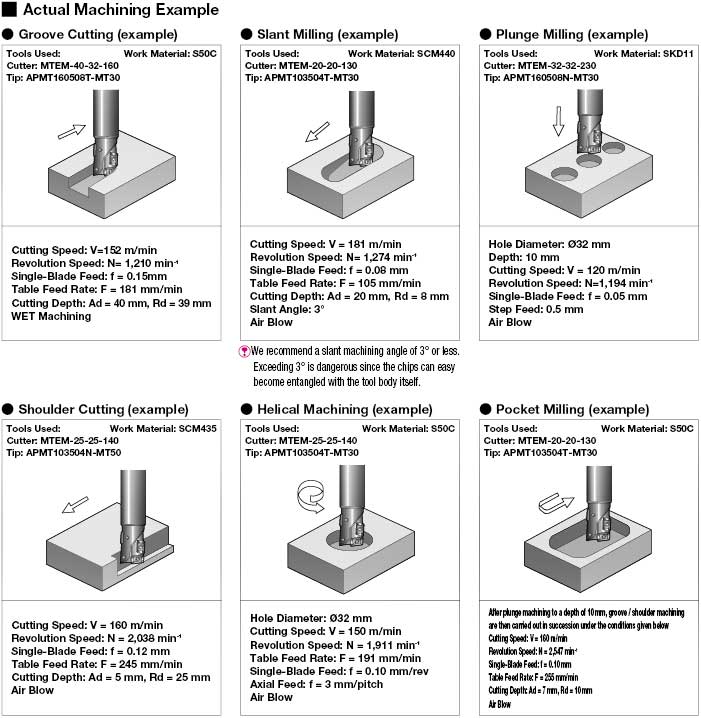

Flat bottom inserts cut effective Z-level and plunge milling with a full 90-degree side wall and multiple standard corner radii.

. Often used for slotting and pocketing cuts in mold and die making they have a 90 profile and rounded corners which reduce flute breakage and chipping. A ball end mill is not the same as a corner radiusbull nose end mill. Ball End Mills are very durable and come with an array of.

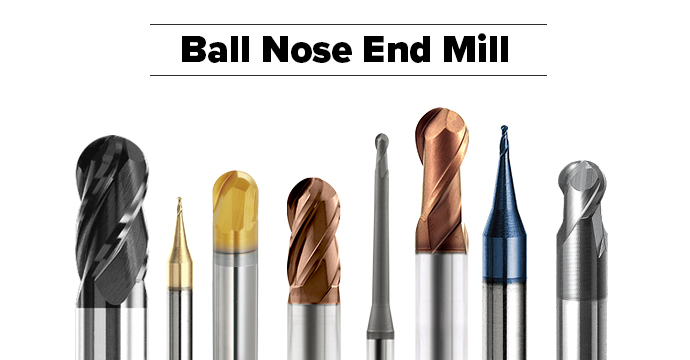

Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations. Bull Nose End Mill. Ball End Mills Ball nose end mills featuring a full radius are ideally suited for milling 3-D contoured parts.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. These have a flat bottom but rounded corners so you can have a filleted. 18 Shank CNC Cutter Milling Carving Bit Set Including 2-Flute Flat Nose Ball Nose End Mill Nano Blue Coat Titanium Coat CNC Bits MC40A.

2 Flute End Mills. The Series 7 End Mill provides precision performance and high production rates without chatter. 164 2-flute flat end mill.

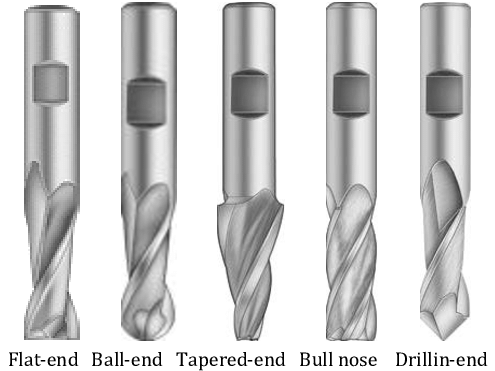

Flat end mill is the end mill with flatsquare end. Also called corner radius end mills this type of cutter is a combination of fishtail and ball-nose also a flat bottom but with rounded corners. Also called Ball Nose End Mills they are used extensively in manufacturing tools dies and machining complex three dimensional contours with a smooth finish.

Variable Pitch End Mills Series 7. 4 Flute End. The ball has a radius with its center point at the center of the end mill so the radius is always 12 of the diameter.

Ball End Mills have a hemispherical tip used to machine rounded details such as the metal bearing grooves found in machines. The full radius or ball shape permits high accuracy contouring and profiling while minimizing corner chipping more prevalent with square and corner radius end mills. I have some ball end mills that I hardly ever use.

It is a general end type for rough millingmore economic compared with ball end mill and corner radius end mill but it is not suitable for machining in speed as high as other two type end mills because too high rotation and feed rate may cause sharp corner blade to break. End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. The most common are flat end mills and ball end mills.

Ball nose end mills R3 made of coated cemented carbide Revolution. This is the tool that can deliver it all in long lengths of cut. Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters.

002 Depth of cut. 18 x 18 x 38 x 3. Single End Ball Number of Flutes.

Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required. Speeds and feeds charts for end mills from The Carbide End Mill Store. Sterling Edges backdraft bullnose inserts are standard for profiling on draft walls requiring chip clearance during the cutting.

Miniature End Mills. Ball Nose End Mill. Bull nose inserts are used in finishing when milling flats and sides.

Ball end mills will leave smaller scallops for the same stepover. The flat end mill is widely used in groove processing side processing and step surface processing. Fishtail Flat Endmills.

Made of cobalt steel these end mills have good heat and wear resistance so they can run at high speeds in hard material. A corner radius end mill has a small radius on each corner the radius is typically 020 030 045 etc. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder.

Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing. Fishtail end mills are generally used to cut simple profiles out of a medium like big letters out of a piece of wood. Corner radius end mill cutters have a stronger milling edge than square end mills so feed rates may be increased and yield longer tool life and greater productivity.

2mm 079 inch Pick feed. Ball nose end mill is a kind of tool which is assembled on the milling machine with the cutter similar to the ball head and is used for milling various curved surfaces and arc grooves. Flat end mills will cut flat areas with no scallops.

End mills in different number of flutes. Bull-nose end mills are often called corner radius end mills and are a combination of fishtail and ball-nose. Online shopping for Ball Nose - End Mills from a great selection at Industrial Scientific Store.

Chatter suppression longer tool life better surface finishes reduced harmonics and improved side-wall straightness. Channeling 4 Ramping 4. WID3 WAB312A008 2 FL REG CARBIDE BALL ENDMILL.

Ø062-500 Cylindrical 2 Flute 30 Helix. All are center cutting allowing plunge cuts into a surface. Bull-nose end mills are often used to mill molds plastic injection molds die cast molds etc 2.

However they leave a terrace-like scallop on non-flat surfaces. The compression end mill creates a smooth surface on top and bottom which is perfect for pre-laminated woods. View Ball End Mill Offering.

03mm 012 inch Air blow dry only Cutting lengthm Flank wearmm 020 015 010 005 000 0 50 100 150 200 Competitor A Competitor B Competitor C Tool life of R3 ball nose end mills. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirementsTo properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process. Bull-nose end mills.

45U_RB - Bull Nose End Mill. Login Dear Customers Our supplier HTC is having substantial problems with supply chains due to Covid-19. 1100 2-flute flat end mil.

End mills come in a variety of shapes.

End Mill Bagian Bagian Dan Jenis End Milling Cutter Pt Yakin Maju Sentosa

Jual Tool 12mm 4 Flute Milling Cutter Tungsten Carbide End Mill Jakarta Barat Lazata Shop Tokopedia

Three Common Shapes Of End Mill Tool Engin Altintas 200112 Download Scientific Diagram

What S The Difference Between Flat Ball Angle Radius End Mill

Products Xinhua Cemented Carbide

End Mills The Essential Beginners Guide

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

What S The Difference Between Flat Ball Angle Radius End Mill

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Cnc End Mill Selection Guide For The Beginners Speed Tiger Cutting Tool

Types Of End Mills Difference Between End Mill And Drill Bit What Is End Milling Cnclathing

Hanzel 5 Things Should Know How To Selecting End Mill

End Mill Bagian Bagian Dan Jenis End Milling Cutter Pt Yakin Maju Sentosa

End Mill Itu Apa Sih Fungsi Dan Kegunaannya Pt Indonesia Surya Sejahtera

General Tool Geometry And Surfaces Of The Various End Mills A General Download Scientific Diagram